It’s an open-source extruder made by Robert Lorincz and it weighs only 140g which is quite impressive. To create a bowden Hermes, simply remove the hotside and fan, then insert the Hermes bowden adaptor. The E3D Hemera can be purchased from the following websites: Amazon E3D Orbiter Extruder If you haven’t heard about the Orbiter extruder, I don’t really blame you. Hemera is interchangeable between Direct and Bowden variants. This reduces the risk of warping and uneven stresses forming in the printed part optimised airflow also means we can supply a quieter fan. To put it simply, we’ve made printing with flexibles easy! Improved airflowĪn optimised heatsink ensures airflow is diverted up and away from both the HotEnd and the heated bed. This means that flexible filaments such as TPU’s can be printed on Hermes with similar print speeds to PLA. As a result of closely tolerancing all the components, we are also able to achieve a clearance gap between filament drive wheels and heatbreak of only 100um. Filament constraintĪlong with a very short filament path from hobb to meltzone, the filament is tightly constrained. Utilise one side for mounting to the printer and the other side for sensors, probes and part-cooling fans. There are 4 T-slots on each side of the motor leaving endless mounting opportunities. Ultimately creating a smaller, more compact system with a lower overall part count. This allows the motor itself to be part of the assembly, incorporating features such as bearing pockets and mounting points. Hemera uses a custom motor based off a NEMA17 frame, modified with our endcap designs. The round bottom of the profile strongly resists filament debris wedging into the drive gear and in almost all cases it’s self-cleaning as any debris simply falls off the teeth.

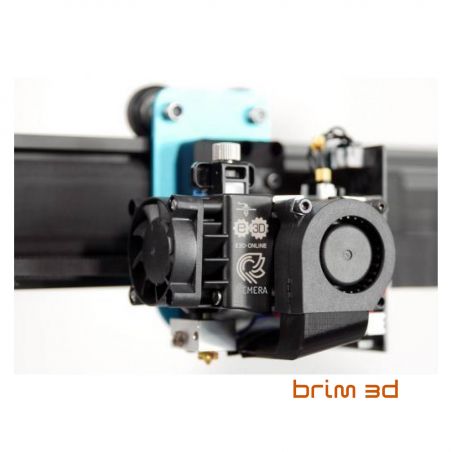

Individually CNC cutting each hobb allows for a round-bottomed root, with a tooth that curves upwards to a robust, sharp tip. Hemera is a dual-drive system with a hardened stainless steel drive train. It can be purchased as a bowden drive setup which includes a bowden adaptor, or as a direct drive extrusion system which includes a heat sink and fan, hemera heatbreak, as well as a ed3 V6 hotend in either 12V of 24V configuration. The Hemera is currently available for 1.75mm filament systems. The Hemera is compatible with both bowden and direct drive extrusion systems and can be used with the E3d Ecosystem of V6, nozzle X, Volcano and SuperVolcano hotends. The Hemera excels in printing regular and flexible materials with precision and control and is even capable of printing flexible filaments at PLA speeds. The dual-drive extrusion system provides exceptional pushing force complete with a fully hardened stainless steel drive train and optimised heatsink design. Introducing Hemera (Formerly known as Hermes),the next generation high performance dual drive extrusion system from e3D avaialble in both direct and bowden A super strong grip and a VERY high torque, easily handles TPU/TPE, attaches to the original Tool parts with s single easy to print part and attaches the motor end with an easy to print single part.

#E3d hemera direct kit full

We are Australian Distributors of the infamous E3D V6 high performance full metal Hot Ends. Not nearly as much weight as a mid sized Nema 17.

0 kommentar(er)

0 kommentar(er)